How can we assist you?

Home Learning Center

From the soap that cleanses your skin to the food you eat, countless everyday items

share a common, natural origin: the palm fruit. The journey from this tropical fruit to

a finished product is a fascinating story of science and innovation. This is the world

of oleochemicals—chemicals derived from natural fats and oils.

While the term "oleochemical" might sound complex, the concept behind it is beautifully

simple. It's about harnessing the power of nature and transforming it through smart

science into ingredients that make our daily lives better, cleaner, and more efficient.

Before you even leave for work in the morning, you've likely interacted with dozens of

products made possible by this hidden science.

At their core, oleochemicals are chemicals derived from renewable sources like vegetable oils, making them a natural alternative to petroleum-based chemicals. We focus on the most significant source: the versatile palm fruit. Natural oils are primarily made of triglycerides, which are molecules containing two key parts: a glycerol backbone and three fatty acid chains. These are the fundamental building blocks of the industry. Through chemical processes like hydrolysis and transesterification, these triglycerides are split into their core components. Once separated and purified, they are transformed into the vast array of ingredients used in products worldwide.

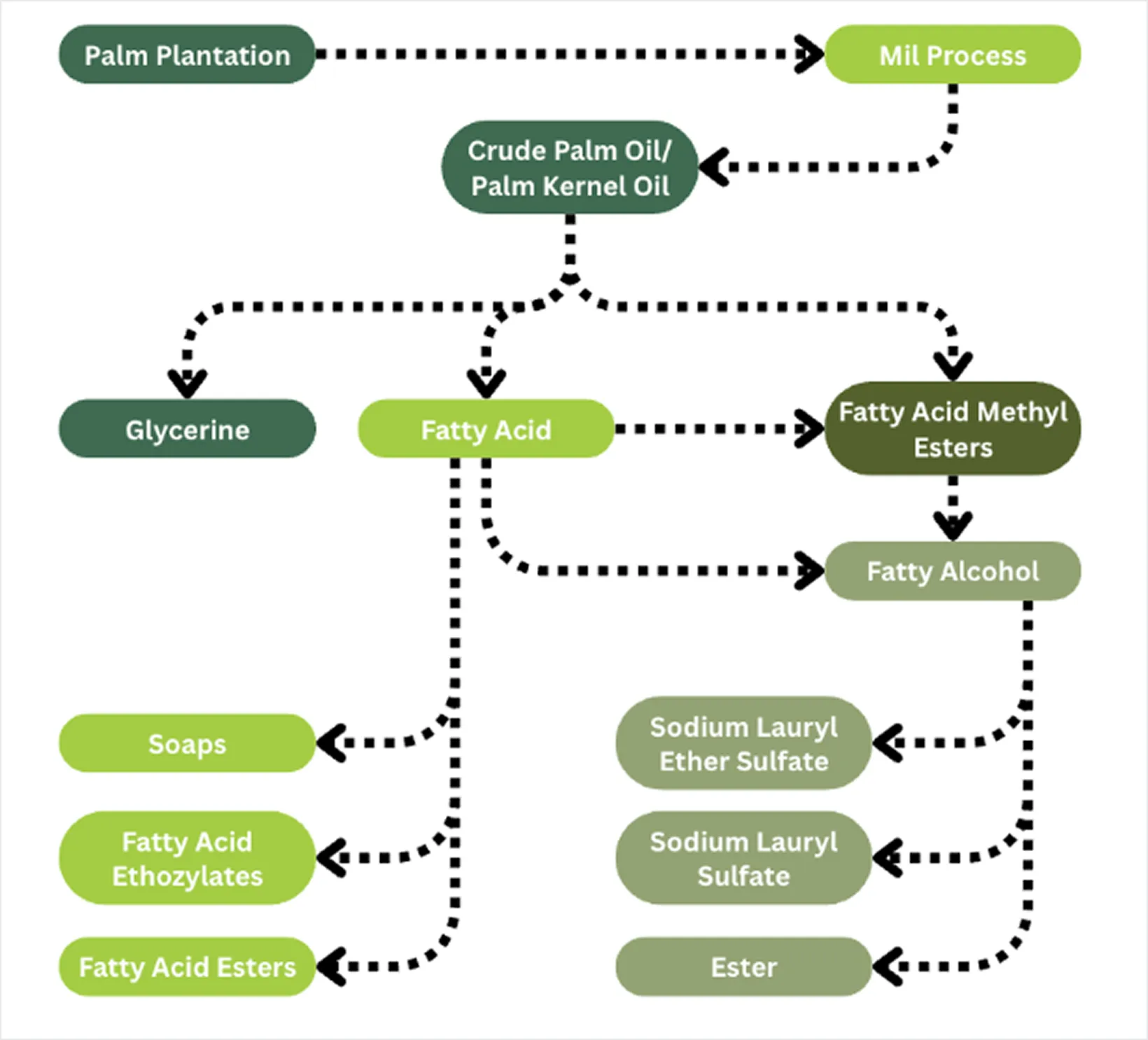

The Manufacturing Journey

The oleochemical production journey begins at the palm plantation, where harvested

fruit undergoes mill processing to produce Crude Palm Oil (CPO) and Palm Kernel Oil

(PKO). These raw oils are then chemically split into two foundational components:

Glycerine and Fatty Acid. While glycerine serves various industrial roles, the fatty

acid acts as a versatile building block used directly to create essential products like

soaps, fatty acid ethoxylates, and fatty acid esters.

Alternatively, fatty acids can be processed into Fatty Acid Methyl Esters (FAME), which

are subsequently converted into Fatty Alcohol. This alcohol serves as the critical

precursor for manufacturing widely used surfactants such as Sodium Lauryl Ether

Sulfate (SLES) and Sodium Lauryl Sulfate (SLS), as well as specialized esters. This

integrated flow demonstrates how palm oil is systematically refined from a raw

agricultural commodity into the complex chemical foundations required for the global

personal care and cleaning industries.

From Palm Fruit to Final Product

| PRODUCT | GRADE | APPLICATION |

|---|---|---|

| Crude Glycerine |

Crude Glycerine 80% Min Crude Glycerine 70% Min Crude Glycerine 80% High MONG |

|

| Refined Glycerine |

Refined Glycerine 99.5% Min Refined Glycerine 99,7% Min (Mixed Animal Fat) Refined Glycerine 99.5% Min USP/BP Refined Glycerine 99,7% USP/BP Refined Glycerine 99,5% USP (Palm Based) Refined Glycerine 99,7% USP Grade Refined Glycerine 99.5% Min USP grade Refined Glycerine 99.7% Min USP/BP Grade Refined Glycerine 99.7% Min USP Refined Glycerine 99.5% Min USP Refined Glycerine 99.7% Min BP Refined Glycerine 99,5% USP Grade Refined Glycerine 99.6% Min |

|

| Stearic Acid |

Stearic Acid B1810 Stearic Acid B1800 Stearic Acid B1801 Stearic Acid 1820 Stearic Acid 1860 Stearic Acid 1838 Stearic Acid 1842 Stearic Acid 1850 Stearic Acid 1865 ST 1 MY ST 8 MY Stearic Acid Sinar FAS (1843) Stearic Acid Rubber Grade |

|

| Soap Noodles |

|

|

| Lauric Acid | Lauric Acid 70% Liquid | A core ingredient in shampoos, body washes, and facial cleansers. |

| Oleic Acid | Oleic Acid 75% | Used in cosmetic formulas for hydration and as a key component in industrial lubricants. |

Presented above represent only a small fraction of the diverse and expansive palm derivatives market. From high-performance lubricants and sustainable plastic additives to advanced surfactants for personal care and high-purity emulsifiers for the food industry, palm derivatives offer unparalleled versatility and bio-based efficiency. As global manufacturing continues to transition toward green chemistry and renewable feedstocks, the applications for these palm derivatives are expanding into new industrial frontiers, reinforcing the role of palm-derived solutions as a cornerstone of the modern bio-economy.

Safety and product quality go hand-in-hand. While most basic oleochemicals—such as fatty acids, alcohols, and glycerin—are generally considered non-hazardous, following rigorous handling and storage procedures is essential.

Always consult the Safety Data Sheet (SDS) before handling any oleochemical.

The oleochemical industry is at the center of the global bio-economy, driven by renewable chemistry and sustainability goals.

We understand that every business is unique. At Tradeasia, we provide tailored oleochemical solutions to meet your specific needs.

Browse ProductHow can we assist you?